Hollow Blow Molding Process

Precision Technology|OEM & Custom|Multi-Industry Applications

Manufacture

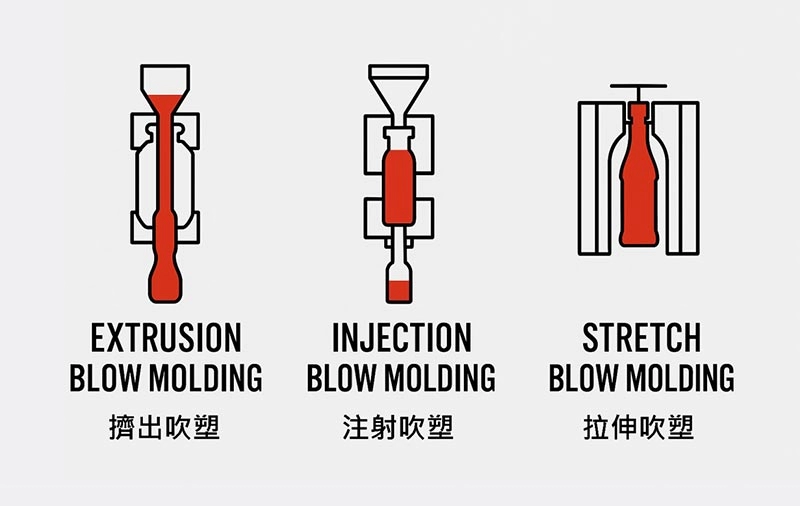

Types of Hollow Blow Molding

- Extrusion Blow Molding

The most common hollow blow molding method, suitable for producing large hollow products. - Injection Blow Molding

A preform is first produced by injection molding, then blow molded.

This method is suitable for producing high-precision and high-quality hollow products. - Stretch Blow Molding

The preform is stretched before blow molding, which increases product strength and transparency.

This method is commonly used for producing bottles and similar products.

-

FeedingPlastic pellets or powder are fed into the hopper.

-

Plasticizing & ExtrusionThe material is heated and plasticized by the screw inside the barrel, transforming into molten plastic.

-

Parison ExtrusionThe molten plastic is extruded through the die head of the extruder, forming a hollow tubular parison.

-

Mold ClosingThe parison is clamped into a pre-designed mold. The mold closes, isolating the parison from the extruder.

-

BlowingHigh-pressure air is blown into the parison, expanding it against the inner wall of the mold to form the desired shape.

-

Cooling & ShapingThe cooling system within the mold solidifies the plastic into its final shape.

-

DemoldingThe mold opens, and the finished plastic product is removed.

-

TrimmingExcess flash or edges are removed from the product.

-

InspectionDimensional checks, leak tests, and other inspections are carried out to ensure product quality.

Fin.