Blow Molding Mold Development

Professional Design|Precision Manufacturing|Quality Assurance

Manufacture

STEP1

Customer Inquiry & Requirement Confirmation

We identify product usage, material selection, appearance requirements, and evaluate feasibility based on durability, chemical resistance, and dimensional needs.

STEP2

Sample Review & Forming Suggestions

Customers provide reference samples. We explain blow-molding characteristics and evaluate feasibility regarding appearance, draft angles, structure, and mass production.

STEP3

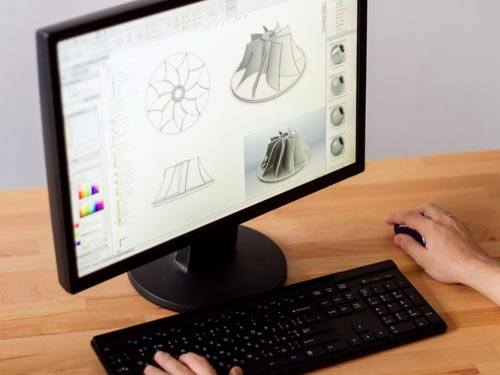

Mold Design & 3D Modeling

A complete 3D mold structure is created, including cooling channels, air needles, and venting systems, ensuring the mold meets production needs.

STEP4

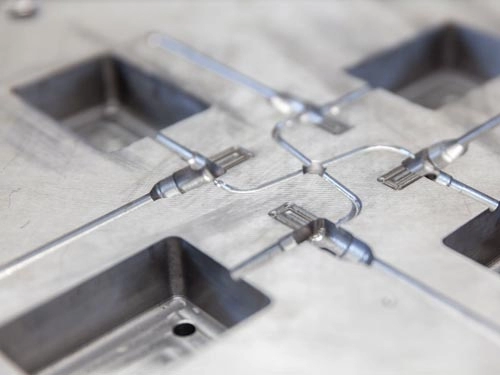

Mold Fabrication & Machining

CNC machining, EDM processing, and mold-base fabrication are performed to ensure dimensional accuracy, cooling efficiency, and surface quality.

STEP5

Trial Molding & Parameter Adjustment

Trial molding is carried out to verify appearance, wall thickness, and dimensional stability. Blow pressure, venting, cooling, and forming conditions are fine-tuned for stable molding.

STEP6

Sample Inspection & Mold Adjustment

Samples undergo checks for appearance, dimensions, sealing, impact strength, and chemical resistance. Mold modifications or parameter adjustments are applied as needed.

STEP7

Mass Production & Shipment

Once molding stability is confirmed, mass production begins with strict QC control. Products are packaged and shipped according to customer requirements with ongoing support.

Fin.