One-Stop Blow Molding Service

Mold Design|Blow Molding Production|Quality Control|Product Delivery

Manufacture

STEP1

Project Inquiry & Requirement Analysis

We review product specifications, application environment, capacity, strength, and chemical-resistance needs. Material options (HDPE, PP, ABS, LDPE) and blow-molding feasibility are evaluated.

STEP2

Sample Review & Molding Feasibility Proposal

Reference samples or similar case studies are provided for evaluation. We recommend suitable blow-molding methods and mold solutions based on shape, thickness, and durability.

STEP3

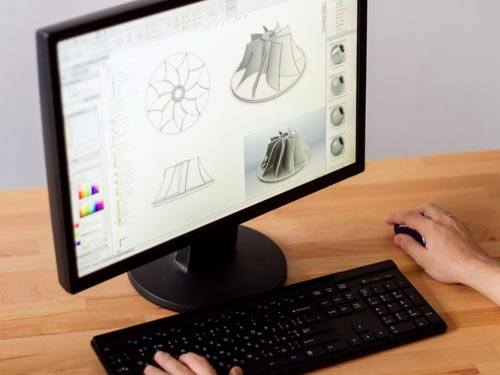

Product Design & 2D/3D Drawing Development

Our engineering team designs the structure and creates 2D/3D drawings. Wall-thickness distribution and load-bearing areas are optimized for stable mass production.

STEP4

Design Confirmation & Project Approval

Final drawings, resin selection, and molding conditions are reviewed and approved. This ensures that the mold and production plan fully meet performance requirements.

STEP5

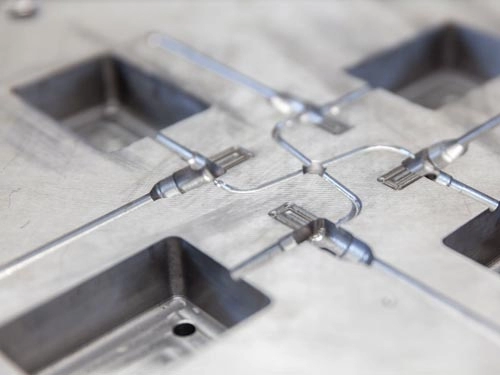

Mold Fabrication & Blow-Molding Trial

The mold is manufactured according to specifications, followed by blow-molding trial runs. Forming parameters including pressure, cooling, and thickness are fine-tuned for optimal performance.

STEP6

Sample Testing & Process Adjustment

Samples undergo impact, leakage, chemical-resistance, and dimensional inspections. Necessary mold or process adjustments are made to achieve final production standards.

STEP7

Mass Production & Full Quality Control

Stable mass production is carried out with strict QC on thickness, dimensions, impact strength, and appearance. All products comply with customer requirements and international standards.

STEP8

Packaging, Logistics & Delivery

Products are packaged securely to prevent deformation during transport. We provide reliable logistics coordination and long-term supply-chain support.

Fin.